Why Choose Acticon

Delivering Manufacturing Excellence with Innovation, Integrity & Reliability.

Diverse Product Range

End-to-End Product Development

- ✔ Custom cosmetic formulation development

- ✔ Regulatory compliance & certification support

- ✔ Label & packaging design

- ✔ Branding & promotional material development

- ✔ Contract manufacturing for skincare, haircare & personal care products

Qualified & Experienced Team

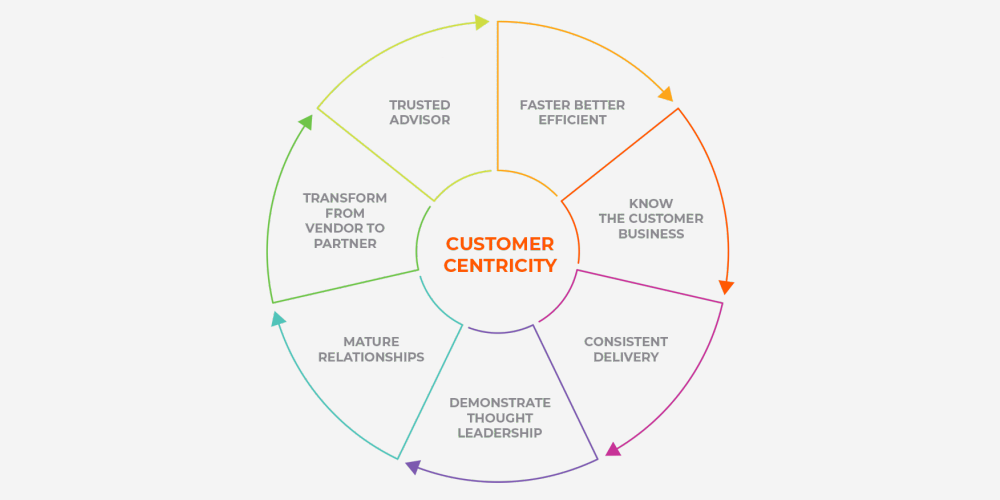

Customer-Centric Approach

Advanced Manufacturing Facility

Large-Scale Production Capacity

Stringent Quality Control & Compliance

- ✔ In-Process Quality Control (IPQC) checks

- ✔ Compliance with MoCRA (USFDA), ISO 22716, GMP, and WHO guidelines

- ✔ Stringent SOPs for consistency and performance

Smart Automation & Efficiency

Brands Developed

75 +

Products Manufactured

600 +

Production Capacity

4500 Kg

Manufacturing Area

40 K sq.ft

Countries Served

20 +

Manufacturing Made Simple

Flexible, Fast, and Cost-Efficient Solutions to Launch and Grow Your Cosmetic Brand

Proven, Market-Tested Stable Formulations

A wide portfolio of stable and effective formulations with a history of successful market performance.

Custom Formulation Capabilities

Tailored ingredient combinations and textures to match your brand’s vision and customer needs.

Low Minimum Order Quantities (MOQs)

Flexible batch sizes to support startups and niche product lines without heavy inventory pressure.

Fast Product Development

Accelerated formulation and sampling process to help you launch faster.

Reduced Packaging Inventory Costs

Optimized packaging strategies to minimize storage needs and financial overhead.

Streamlined Production & Delivery

End-to-end services that simplify the entire process from manufacturing to final shipment.

No Infrastructure Investment Needed

Launch and grow your brand without the capital burden of setting up a manufacturing facility.

Exclusive Brand-Centric Products

Develop products that are unique to your brand—formulas, claims, and packaging aligned with your identity.

Frequently Asked Questions

If you have already evaluated and selected a specific supplier for RM or PM, we can collaborate with them. We are happy to procure materials from your preferred suppliers, ensuring all sourcing aligns with the terms you have established with them. This flexibility allows us to adapt to your unique preferences while maintaining our commitment to product quality and consistency.

In this way, we balance flexibility with rigorous quality assurance, ensuring your products are manufactured to the highest standards while accommodating your specific sourcing needs.

If you choose a supplier, please share their details with us. Our purchase team will evaluate their reliability and assess whether the packaging is compatible with the product and our manufacturing technology. If we identify any concerns, we will inform you and proceed based on your guidance. Payments to the supplier will follow agreed terms, provided your payments to us are cleared.

Please share the supplier's details and the ingredient specifications with us. Our purchase team will evaluate the supplier (if they are new) and may request samples for quality assessment by our QA team. If any concerns arise, we’ll inform you and proceed based on your input. Payments to the supplier will follow agreed terms, provided your payments to us are up to date.

At Acticon, our goal is to prevent quality issues before products ever leave our facility — ensuring that you receive products of the highest standard. We achieve this through rigorous quality control and assurance processes aligned with ISO 22716, ISO 9001, and ISO 13485 certifications. To further support transparency, we also accommodate third-party inspections upon request.

Preventing Quality Issues:

Every production batch is thoroughly tested prior to dispatch. This includes checks for formulation stability, packaging integrity, and compliance with your approved specifications — helping us ensure that no manufacturing defect reaches your customers.

Managing Consumer Complaints:

We take full accountability for any issues related to the manufacturing process (such as product texture inconsistencies or ingredient variances). However, some complaints may arise from factors beyond our control — for example, improper storage, transport damage, or unmatched marketing claims. In such cases, we collaborate closely with our clients, offering guidance on resolution strategies to uphold customer satisfaction and safeguard your brand’s reputation.

Partner with Acticon

Powering Trust With Proven Certifications

International benchmarks for safety, efficacy, and sustainable manufacturing practices